|

|

|

|

Three-Dimensional Reality

Seven unbeatable reasons for choosing

DiSHAPE by MiCROTEC:

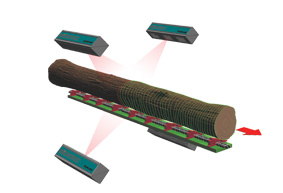

The new DiSHAPE by MiCROTEC is the logic successor to the consolidated TRUESHAPE system and incorporates the new DiSCAN100 3D measurement module. This innovative system is unmatched in the 3D log and lumber measurement today and represents the most advanced technology globally on the market. The combination of laser triangulation and the DiSCAN 100 differential reflected light scanning, DiSHAPE forms realistic 3D image representations of logs and lumber without any shadows from chain bars or other obstructions. It not only registers all depressions, but also sweep and ovality of the log. Furthermore the exact position of the ovality is precisely recorded. Combined with supported optimization programs such as WiNLOG by MiCROTEC, DiSHAPE gives our customers significant advantages over their competition. Mills equipped with MiCROTEC technology are evidently leaders in fiber utilization, lumber recovery, and economic efficiency.

|

|

|

Copyright 2004-2006 ~ Barr-Mullin, Inc. |