|

|

|

|

Uncovering The Naked Board

Seven convincing reasons for choosing

BOARDSCAN by MiCROTEC:

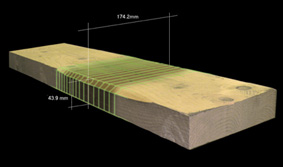

The different optimization programs by MiCROTEC, such as VARiOSORT and Optiline, need accurate measurements values. BOARDSCAN is the all-encompassing concept for 3 measurement systems for establishing the length, width and thickness of the board feeded crossways. It works well at conveyor speeds of up to 300m per second and handles conveniently 240 boards per minute. Both length and side transport directions are supported which adds to the versatility of the system. The BOARDSCAN systems can be adjusted customized according to needs to meet different quality and accuracy requirements in each mill. To realise this, appropriate light barriers, shields, cameras, infrared barriers and/or the new DiSCAN by MiCROTEC can be routinely used. The BOARDSCAN systems by MiCROTEC can be adapted in numerous and flexible ways to external interfaces. It can be installed easily in existing plants and millsfrom different suppliers without difficulties. The intelligent design allows the system to integrate even to installations other than MiCROTEC.

|

|

|

Copyright 2004-2006 ~ Barr-Mullin, Inc. |